一、用途

I. Purpose

DKJ-B型电动执行机构,是DDZ型电动单元组合仪表中的执行单元,它接受调节单元信号,自动地操纵执行机构完成调节任务,广泛地用于电力、化工、石油、冶金、建材、轻工等行业。

DKJ-B electric actuator is the execution unit of DDZ-type packaged electronic instruments, it accepts the signal of regulating unit and automatically controls the actuator to complete regulating task, is widely used in electric power, chemical, petroleum, metallurgy, building materials and light industry, etc.

DKJ-B型电动执行器采用隔爆结构,防暴等级为dⅡBT3,可在规定的爆炸性环境中使用(使用范围参考GB3836·1-2000《爆炸性气体环境用电气设备第二部分:隔爆型“d”》)。

DKJ-B electric actuator uses explosion-proof structure and the explosion-proof grade is dⅡBT3, can be used in specified explosive environment (the scope of application refers to GB3836·1-2000 Part II: Explosion-proof-type ‘d’ of Electrical Equipment Used in Explosive Gas Environment).

DKJ-B型电动执行机构,配接DFD型电动操作器经DFC型伺服放大器可完成调节系统的“手动-自动”的无扰动切换。及被调节对象的自动调节及远方手动操作。

DKJ-B electric actuator is equipped with DFD–type electric operator, via DFC servo amplifier to complete non-disturbance switch of ‘manual - automatic’ of regulating system, as well as regulated object’s automatic regulating and remote manual operation.

二、规格型号

II. Specification and Model

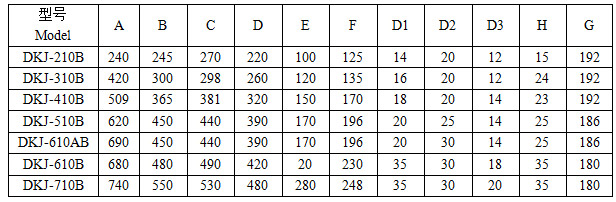

DKJ-B型电动执行机构规格型号见表1。

The specification and model of DKJ-B electric actuator are as shown in Table 1.

表1

Table 1

三、注意技术指标

III. Pay Attention to Technical Indicators

(1)基本误差限:±2.5%

(1) Basic error limit: ±2.5%

(2)回差:≤1.5%;

(2) Return difference: ≤1.5%;

(3)死区:≤3%;

(3) Dead zone: ≤3%;

(4)阻尼特性:≤3次办周期;

(4) Damping characteristics: ≤3 times running cycle;

(5)电源:单相电压220V,频率50HZ

(5) Power supply: single phase voltage 220V, frequency 50hZ

(6)使用环境:

(6) Use environment:

温度:执行机构-10~+55℃或-25~+℃;放大器0~50℃;

Temperature: actuator -10~+55℃ or -25~+℃; Amplifier 0~50℃;

相对湿度≤95%;

Relative humidity≤95%;

空气中允许含有传爆能力不高于Ⅱ类B级T3组的爆炸性气体,但不含有腐蚀性气体。

The air is allowed to contain explosive gas, which detonation propagation ability is not higher than ⅡBT3, but not contain corrosive gases.

四、产品特点

IV. Product Features

(1)本产品结构合理,生产工艺及质量管理严格,保证了执行机构可靠性高,平均无故障时间MBTF>25000小时。

(1) The structure is reasonable, the production technology and quality management are strict, what ensures the actuator has high reliability and mean free error time MBTF>25000 hours.

(2)位置发送器转换电路抗感应电压能力强,电路能直接承受高的冲击电压而不损坏,其性能超过国内同类产品。

(2) The ability of anti-induction voltage of conversion circuit of position transmitter is strong, the circuit can directly withstand high impact voltage without damage and the performance is more than similar products in the country.

(3)执行机构采用交流单相电机,给自控系统的使用带来方便。

(3) The actuator uses AC single phase motor, to bring convenience to the use of automatic control system.

五、结构与工作原理说明

V. Structure and Working Principle Description

比例式电动执行机构是一个以两相伺服电动机为动力源的位置伺服机构,由电动伺服放大器和积分式电动执行机构组成,积分式电动执行机构由两相伺服电动机、减速器和位置发送器组成。

Proportional electric actuator is a position servo mechanism with a two-phase servo motor as the power source, is composed of electric servo amplifier and integral electric actuator. Integral electric actuator is composed of two-phase servo motor, reducer and position transmitter.

对于比例式执行机构,当伺服放大器的输入端有控制信号输入时,此信号与来自位置发送器的位置反馈信号进行比较,比较后的信号偏差经过放大使功率级导通相应回路以驱动两相伺服电动机转动,使减速器的输出轴朝着减小这一偏差方向转动(位置发送器不断将输出轴的实际位置转变为电信号一位置反馈信号送回伺服放大器)直到信号偏差小于死区为止,此时输出轴就稳定在与输入信号相对应的位置上。输出轴的行程与输入信号成比例关系。

In view of proportional actuator, when the input end of servo amplifier inputs control signal, the signal will be compared with position feedback signal from position transmitter, after comparison, the signal deviation is amplified and power-level is guided through the corresponding circuit to drive two-phase servo motor to rotate, so as to the output shaft of reducer rotates towards to the direction of deviation reduction (position transmitter constantly changes actual position of output shaft to position feedback signal of electrical signal and returns to servo amplifier) until the signal deviation is less than the dead zone, at this time, the output shaft will be stable in the position corresponding to input signal. The stroke of output shaft has proportional relation with input signal.

对于积分式执行机构,置电动操作器为“手动”状态,按下电动操作器的“关”或“开”按钮,伺服电动机通电旋转,减速器的输出轴朝着“关”或“开”的方向转动,位置发送器将输出轴的实际不断转变为电信号-位置反馈信号送回电动操作器的阀位开度表,当阀位开度表的反馈信号显示输出轴已经转到需要的位置时,放开电动操作器的按钮,伺服电动机断电停转,输出轴停止转动,输出轴的转动量与通电时间成积分关系。

In view of integral electric actuator, place electric operator in ‘manual’ state, press ‘Off’ or ‘On’ button of electric actuator, the servo motor will be set up an electric circuit and rotate, the output shaft of reducer will rotate towards the direction of ‘Off’ or ‘On’, the position transmitter will constantly change actual situation of output shaft to electrical signal - position feedback signal, and return to valve opening scale of electric actuator, when the feedback signal of valve opening scale shows that the output shaft has rotated to required position, should release the button of electric actuator, then the servo motor will be powered off and stop rotating, the output shaft will stop rotating, the rotation of output shaft has integral relation with energized time.

电动机为鼠笼式两相交流伺服电动机。该电动机转子内阻大,具有较大的起动转矩和较软的机械特性。在伺服电动机的尾部装有制动装置,能在电动机失电后迅速制动,有效地限制输出轴的惯性惰走及负载反作用力矩的影响,使输出轴准确地停止在确定的位置上,改善系统的稳定性。DKJ-B电动执行机构采用交流电容器做为伺服电动机的分相电容,提高了产品的可靠性。

The motor is squirrel cage type two-phase AC servo motor. The rotor of motor has large inner resistance, with larger starting torque and soft mechanical properties. The tail of servo motor is equipped with braking device, can quickly brake after the motor has power failure, can effectively limit output shaft’s inertial idler and the influence of load reaction torque so that the output shaft can be accurately stopped at a certain position and improve the stability of the system. DKJ-B electric actuator uses AC capacitor as the split-phase capacitor of servo motor, to improve the reliability of the product.

减速器采用一级圆柱齿轮和一级渐开线少齿差行星齿轮传动,具有传动比大、体积小、效率高、噪音小、寿命长等特点,在减速器上设置了手轮装置供就地调整和操作用,手轮转动方向与输出轴相同。

The reducer uses first stage cylindrical gear and first stage involute planetary gear with few teeth difference to drive, has the characteristics of large transmission ratio, small volume, high efficiency, low noise and long service life, etc. The reducer is equipped with hand wheel device for local adjustment and operation, the rotation direction of hand wheel is the same as the output shaft.

伺服电动机安装在减速器上,它的后罩上有手柄,可以左右转动进行“手动”与“电动”状态切换,在安装调试及系统或线路出现故障时可断开电源,拉出手轮至“手动”位置(电动机的手柄也扳至“手动”位置)进行就地操作。

Servo motor is installed in the reducer and the back cover has a handle to rotate in left or right to switch the state of ‘manual’ or ‘electric’. The power supply can be disconnected when installing, debugging or system or circuit has failure, pull-out the hand wheel to ‘manual’ position (the handle of the motor is also pulled to ‘manual’ position) for local operation.

除断电进行手动就地操作之外,手轮及电动机手柄务必置于“电动”位置。

In addition to manual local operation under interruption of power supply, the hand wheel and motor’s handle must be placed in ‘electric’ position.

减速器的端盖上配有两块由T型槽螺栓和螺母紧固的制动块,这就是角行程执行机构的机械限位装置。

The end cover of the reducer is equipped with two brake blocks fixed by T-type groove bolt and nut, and this is mechanical limit device of angular stroke actuator.

位置发送器由传动装置、传感元件、电源装置、放大电路及凸轮-微动开关等组成。输出轴通过齿轮带动凸轮和导电塑料电位器转轴转动,将输出轴的转角变化转换为电位器的电阻变化继而通过放大电路转化成位置反馈电流作为位置发送器的输出信号,在放大器电路印制线路板上装有两个电位器:“0%”电位器和“100%”电位器分别用来调整位置反馈电流的下限和上限。

The position transmitter is composed of transmission device, sensing element, power supply device, amplifying circuit and cam – micro switch, etc. The output shaft is rotated through gear to drive cam and conductive plastic potentiometer shaft, and converts the angular variation of output shaft to resistance change of the potentiometer, then by amplifying circuit to convert to output signal of position feedback current, as the position transmitter. The amplifier circuit printed circuit board is equipped with two potentiometers: ‘0%’ potentiometer and ‘100%’ potentiometer, what are respectively used to adjust the upper and lower limit of position feedback current.

模块化位置发送器实现了位置反馈电路的微型化、模块化、免维修,技术指标有所改善,可工作于较恶劣的环境。

Modular position transmitter realizes the miniaturization, modularization and free maintenance of position feedback circuit, the technical indexes are improved and can be used in the bad environment.

在带动导电塑料电位器转动的轴上装有外可调的凸轮可以分别使2个微动开关动作。靠近导电塑料电位器的凸轮-微动开关可以切断输出轴顺时针转动(面对输出轴观察。注:以下均如此)的电动机回路,另一个凸轮-微动开关可以切断使输出轴逆时针转动的回路。这两组凸轮-微动开关组成了执行机构的电气限位装置。

The shaft of driving conductive plastic potentiometer to rotate is equipped with adjustable cam to respectively make two micro switches act. The cam – micro switch is close to conductive plastic potentiometer and can cut off motor return circuit of clockwise rotation of output shaft (observe in the face of the output shaft. Note: all of the following are the similar), the other cam – micro switch can cut off the return circuit of counterclockwise rotation of output shaft. These two cam – micro switches constitute electrical limit device of the actuator.

六、电动执行机构的校核

VI. Check of Electric Actuator

每台电动执行机构在出厂前均已按标准进行了严格检验,考虑到运输及贮存影响,为确保使用安全,请用户在安装使用之前进行如下校核:

Before leaving the factory, each electric actuator has been strictly tested according to the standards, taking into account the impact of transport and storage and in order to ensure the safety of use, please carry out the following check before installation and use:

1、使用现场的动力条件、环境条件符合本说明书第三章的规定。

1. The dynamic and environmental conditions of the field meet the provisions of Third Chapter of this manual.

七、电动执行机构的安装、调整、使用与维护

VII. Installation, Adjustment, Use and Maintenance of Electric Actuator

1、安装

1. Installation

1.1、伺服放大器的安装

1.1 Installation of servo amplifier

伺服放大器为控制室内安装使用的仪表。

Servo amplifier is the instrument installed and used in the control room.

伺服放大器有两种安装形式:

Servo amplifier has two installation forms:

墙挂式结构可垂直安装在控制柜内的金属架立柱上,架装式结构安装在控制柜内的机架上。

The wall-hanging structure can be vertically installed on the metal frame upright column of the control cabinet, and the frame mounting structure can be installed on the frame of the control cabinet.

伺服放大器的外形及安装尺寸按伺服放大器安装使用说明书的规定。

The dimension and installation size of servo amplifier should follow the provisions of servo amplifier installation manual.

1.2、电动执行机构的安装

1.2 Installation of electric actuator

执行机构安装在混凝土或金属骨架的基座上并用地脚螺钉紧固。执行机构的输出臂终端可通过球型铰链与调节机构连接。

The actuator is installed in the base of concrete or metal frame and fastened by anchor bolt. The output arm end of the actuator can be connected to regulatory mechanism through a ball-type hinge.

执行机构在出厂时已加润滑脂。

When leaving the factory, the actuator has been added lubricating grease.

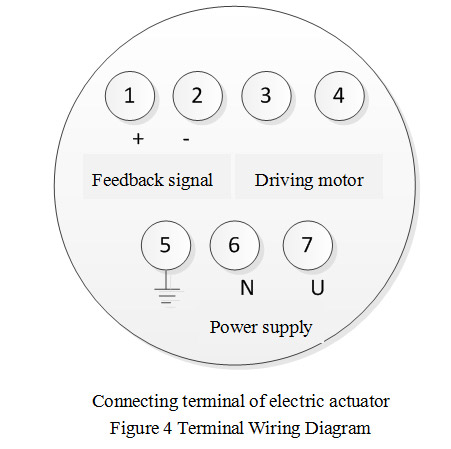

电动执行机构的外形及安装尺寸见图3,接线端子见图4.

The dimension and installation size of electric actuator are as shown in Figure 3, the connecting terminal is shown in Figure 4.

2、调整

2. Adjustment

(所有开盖,带电调整工作均应在不含有爆炸性气体的环境中进行)

(All works of opening cover and electrification adjustment should be carried out in the environment of not contain explosive gases.)

2.1、机械限位装置的调整

2.1 Adjustment of mechanical limit device

松开紧固制动块的螺母,将手轮手柄置于“手动”位置,摇动手轮使输出轴转动到对应于反馈电流下限的位置(以下简称下限位置),使一个制动块贴住输出臂,紧固好固定制动块的螺母,摇动手轮(正作用时逆时针转动,反作用时顺时针转动),使输出轴转动90(此位置以下简称上限位置),使另一个制动块贴住输出臂另一侧,紧固好螺母。

Loosen the nut, which fastens the brake block, place the hand wheel’s handle in ‘manual’ position, shake the hand wheel so that the output shaft rotates to the position of corresponding to feedback current lower limit (hereinafter referred to as lower limit position), make a brake block stick to the output arm, fasten the nut, which fixes the brake block, shake the hand wheel (counterclockwise rotation under direct action and clockwise rotation under reaction) so that the output shaft rotates 90 (hereinafter referred to as upper limit position), make the other brake block stick to the other side of output arm and fasten the nut.

2.2、电气限位装置的调整(本节以正作用方式为例叙述)

2.2 Adjustment of electric limit device (this section is described in direct action as an example)

拆下位置发送器盖,卸下驱动电机的引线,摇动手轮使输出轴转动到下限位置,松开紧固凸轮的圆螺母,手握最里面的凸轮使其逆时针转动接近并压动微动开关-S2,拧紧圆螺母;摇动手轮使输出轴转动到上限位置,稍微松开圆螺母,使靠近圆螺母的凸轮顺时针转动接近并压动微动开关-S1,拧紧圆螺母。

Remove the cover of position transmitter, remove the lead wire of driving motor, shake the hand wheel so that the output shaft rotates to the lower limit position, loosen the round nut, which fastens the cam, hold the innermost cam and make it carry out counterclockwise rotation, close to and press micro switch-S2, then tighten the round nut; Shake the hand wheel so that the output shaft rotates to the upper limit position, loosen the round nut slightly and make the cam of close to the round nut carry out clockwise rotation, close to and press micro switch-S1, then tighten the round nut.

2.3、正作用执行机构工作状态的调整

2.3 Adjustment of actuator working condition under direct action

2.3.1、正作用执行机构位置反馈信号的调整

2.3.1 Adjustment of position feedback signal of actuator under direct action

按本说明书的接线图(图4)接线

Connection according to the wiring diagram of the manual (Figure 4)

电源的相线、N线不能接错接地必须牢固可靠,输入信号及反馈信号通道必须使用屏蔽接线

The phase line and N line of power supply cannot be wrong, the grounding must be reliable. The channel of input signal and feedback signal must use shielded wire.

置电动操作器为“手动”状态,接通电源,调整操作器面板上的电位器使输出信号电流为4mA,执行机构输出轴逆时针转动,位置反馈信号减小(可能在每一瞬间反馈电流减小到小值时突变至大值后继续减小)。当输出轴转动到下限位置时,微动开关-S2被凸轮压动,电动机失电停转,输出轴停在额定行程下限。松开固定导电塑料电位器的2个压板,缓慢转动导电塑料电位器的外壳如果反馈电流趋于减小则当其突变为大值后方向旋转该电位器的外壳,当反馈电流变到小值再继续转动越过反馈电流(亦即电位器的电阻)的不稳定区当其呈持续上升状态时紧固好压板;如果反馈电流趋于增大则当其突变到小值后再继续转动越过反馈电流(亦即电位器的电阻)的不稳定区当其呈持续上升状态时紧固好压板;用改锥调整位置反馈单元模块上的0%电位器使位置反馈电流为工作信号范围下限。

Place electric operator in ‘manual’ state, switch on the power, adjust the potentiometer of actuator panel to make output signal current be 4mA, the output shaft of actuator carries out counterclockwise rotation and position feedback signal is reduced (the feedback current maybe reduced to minimum in each moment, suddenly to the maximum and then continue to reduce). When the output shaft rotates to the lower limit position, micro switch-S2 is pressed by the cam, the motor is switched off and the output shaft stops at the lower limit of rated stroke. Loosen the two press plates of fixing conducive plastic potentiometer, slowly rotate the shell of conducive plastic potentiometer, if the feedback current tends to reduction, should rotate the shell of the potentiometer when it suddenly changes to the maximum, when the feedback current is the minimum, continue to rotate over the unstable area of feedback current (i.e., the resistance of the potentiometer), when it is in a continuous rise state, should fasten the press plates well; If the feedback current tends to increase, should continue to rotate over the unstable area of feedback current (i.e., the resistance of potentiometer) when it suddenly changes to the minimum, when it is in a continuous rise state, should fasten the press plates well; Use a screwdriver to adjust 0% potentiometer of position feedback unit module so that position feedback current is in the lower limit of working signal range.

假设已按上图接线。

It is assumed that has been wired according to above diagrams.

接通电源。置电动操作器“自动”状态。在操作器输入端施加工作信号范围下限的输入信号,位置定位器“下行”指示灯亮,伺服电动机驱动执行机构输出轴逆时针转动,位置反馈信号向接近输入信号的方向变化,当它们的代数差小于位置定位器的死区时位置定位器“下行”指示灯熄灭,伺服电动机失电停转,执行机构输出轴停止转动。

Switch on the power. Place the electric operator in ‘automatic’ state. Apply input signal of working signal range lower limit in the operator’s input end, the position locator ‘downstream’ indicator lights, the servo motor drives the actuator’s output shaft to carry out counterclockwise rotation, the position feedback signal changes towards to the direction of close to input signal, when their algebraic difference is less than the dead zone of position locator, the position locator’s ‘downstream’ indicator lights off, the servo motor loses power to stop rotating and the output shaft of actuator stops rotating.

如果微动开关-S2已被压动即执行机构输出轴已经达到额定行程下限而位置定位器“下行”指示灯仍亮时,则调整反馈单元模块的“0%”电位器,减小位置反馈电流使之为工作信号范围下限使位置定位器“下行”指示灯熄灭。

If micro switch-S2 has been pressed, namely, the output shaft of actuator has reached the lower limit of rated stroke and position locator ‘downstream’ indicator still lights, should adjust ‘0%’ potentiometer of feedback unit module, to reduce position feedback current so that it is within the lower limit of working signal range, and position locator’s ‘downstream’ indicator lights off.

如果位置定位器“下行”指示灯熄灭,而微动开关-S2没有被凸轮压动即执行机构输出轴还未到达额定行程下限时,则调整位置反馈单元模块的“0%”电位器,增加位置反馈电流,使位置定位器“下行”指示灯重亮,执行机构输出轴继续逆时针转动,直到微动开关-S2被凸轮压动而位置定位器“下行”指示灯熄灭为止。

If position locator’s ‘downstream’ indicator lights off and micro switch-S2 has not been pressed by cam, namely, the output shaft of actuator has not reached the lower limit of rated stroke, should adjust ‘0%’ potentiometer of position feedback unit module, to add position feedback current, so that position locator’s ‘downstream’ indicator lights again, the output shaft of actuator continues to counterclockwise rotation until micro switch-S2 is pressed by the cam and position locator’s ‘downstream’ indicator lights off.

在位置定位器的输入端施加工作信号范围上限的输入信号,用类似的方法调整执行机构上限的工作状态。调整完毕安装好位置发送器的罩盖。

Apply input signal of upper limit of working signal range in the position locator’s input end, by the similar method to adjust the working state of the upper limit of actuator. After adjustment, install the cover of position transmitter.

2.3.3、反作用执行机构位置反馈信号调整

2.3.3 Adjustment of position feedback signal of actuator under reaction

安照2.3.1的方法调整,当执行机构输出轴顺时针转动使微动开关-S1动作时,调整位置反馈信号为工作信号下限;当执行机构输出轴逆时针转动使微动开关-S2动作时,调整位置反馈信号为工作信号范围上限。

Adjust according to 2.3.1 method, when the output shaft of actuator has clockwise rotation and makes micro switch-S1 act, should adjust position feedback signal as the lower limit of working signal; when the output shaft of actuator has counterclockwise rotation and makes micro switch-S2 act, should adjust position feedback signal as the upper limit of working signal range.

2.3.4、反作用比例式执行机构工作状态的调整

2.3.4 Adjustment of reaction proportional actuator working condition

参照2.3.2的方法进行。

Carry out according to 2.3.2 method.

3、使用

3. Use

通电运行前务必仔细检查接线是否正确,手轮是否置于“电动”位置。

Before power on and operation, please be sure to carefully check whether the wiring is correct, whether the hand wheel is placed in ‘electric’ position.

电动执行机构有3种操作方式;

Electric actuator has three operation ways:

A、“自动”操作——接受系统的控制信号自动操作。

A. ‘Automatic’ operation – automatically operate after receiving the control signal of the system.

B、“手动”操作(远方控制)——人为给定信号使执行机构实现电动操作。

B. ‘Manual’ operation (remote control) – human gives signal to make the actuator implement electric operation.

C、就地操作——断开电源,操作人员转动手轮对执行机构实行就地操作。

C. Local operation – disconnect the power and the operator rotates the hand wheel to implement local operation to the actuator.

自动操作:对于比例式执行机构,当接入电动操作器时,需将操作器的转换开关旋钮旋至“自动”位置,即可实现自动操作。

Automatic operation: in view of proportional actuator, when connects to electric operator, need to turn the switch valve knob to ‘automatic’ position, then can achieve automatic operation.

手动操作:把操作器按钮转至“手动”位置。

Manual operation: turn the operator button to ‘manual’ position.

就地操作:主要用于安装调试或系统、线路出现故障时,用手轮进行就地操作。

Local operation: is mainly used for installation, debugging, or failure of system or circuit, at this time, carry out local operation by hand wheel.

4、维护

4. Maintenance

执行机构应经常进行维护。

The actuator should be regularly maintained.

对于震动较大的场所,应经常检查紧固件是否松动,接插件接触是否良好,锁紧是否可靠并及时维修。

The places with larger vibration should be regularly checked whether the fastening pieces are loosened, whether the contact of connectors is good, whether the locking is reliable and maintained in time.

使用频繁的执行机构每运行一年半应大修一次。

The actuator with frequent use should be overhauled once each running for a year and a half.

应仔细清洗零部件,更换全部紧固件及磨损的零部件

Should carefully clean the parts and replace all fasteners and worn parts.

应清除所有的润滑脂,重新装填新的润滑脂。

Should remove all lubricating grease and refill the new grease.

在检修各电气装置时,注意更换损坏的原件及老化的导线,更换全部微动开关。

When overhauling the electrical equipment, should pay attention to replace the damaged original and aging wire, as well as replace all micro switches.

在将位置发送器装在减速器时务必注意使各密封件的有效工作。

When the position transmitter is installed in the reducer, should be sure to effective work of the seals.

用500V兆欧表检查各组导线间及其与外壳的绝缘电阻。

Use 500V magneto-ohmmeter to check insulation resistance between the conductors and shell.

按本说明书的规定接线、调整和安装执行机构

Wire, adjust and install actuator according to the provisions of the manual.

八、贮存

VIII. Storage

产品贮存在温度-10~+40℃,相对湿度不大于80%的通风室内,周围空气不得含有对产品起腐蚀或其他损坏作用的介质。贮存期超过18个月的执行机构在使用前应更换减速器内的润滑剂。

The product should be stored in the ventilation room with temperature -10~+40℃ and relative humidity is not more than 80%, the surrounding air should not contain the media with corrosion or other damage to the product. In view of the actuator with storage period of more than 18 months, should replace the lubricating grease of reducer before use.

九、保证事宜

IX. Guarantee Matters

在正常情况下,自发货之日起12个月本公司对产品免费维修。

Under normal circumstances, the company will give free maintenance to the product within 12 months from the date of delivery.

对于逾期或用户违反说明书的规定误安装或操作造成产品损坏本公司可应用户要求进行维修,但将收取相应的费用。

For the situations of overdue or product damage caused due to error installation or operation of the user violates of the provisions of the manual, the company can repair according to the requirements of the user, but will charge the appropriate fee.

订货须知

Order Notice

用户订货请说明如下内容:

When ordering, please describe the following contents:

阀门所需转矩(N.m),转速(r/min)

Torque required by valve (N.m), speed (r/min)

阀杆直径(mm)

Valve stem diameter (mm)

法兰型式与尺寸

Flange type and size

产品规格型号

Product specification and model

各种特殊要求

Various special requirements

天津市佰纳德自控仪表技术开发有限责任公司

Tianjin Bai Nader Automation Instrument Technology Development Co., Ltd

公司地址:天津市北辰区联东U谷131-3

Address: 131-3, Liandong U Valley, Beichen District, Tianjin

电话:022-27618979 022-27642348

Phone: 022-27618979 022-27642348

传真:022- 27642348

Fax: 022- 27642348

网址:http://www.bndyb.cn

Website: http://www.bndyb.cn

上一信息:DZW15直行程

下一信息:DZW15配DN50瓷刀闸阀